Water Clear Polyurethane

Click HERE to view our Polyurethane Guide

Our Water Clear Polyurethane range is designed for projects that demand high clarity and precision. Available in both rigid and flexible formulations, these resins are ideal for clear casting, encapsulation, props, lenses, and artistic applications where transparency is key.

These systems cure to a glass-like finish with excellent detail reproduction, making them a top choice for professionals working in FX, prototyping, and decorative pieces. Pair with dyes or tints for stunning translucent effects, or leave clear for a polished, clean result. These systems also outperform standard polyurethanes when it comes to UV and environmental resistance and stability.

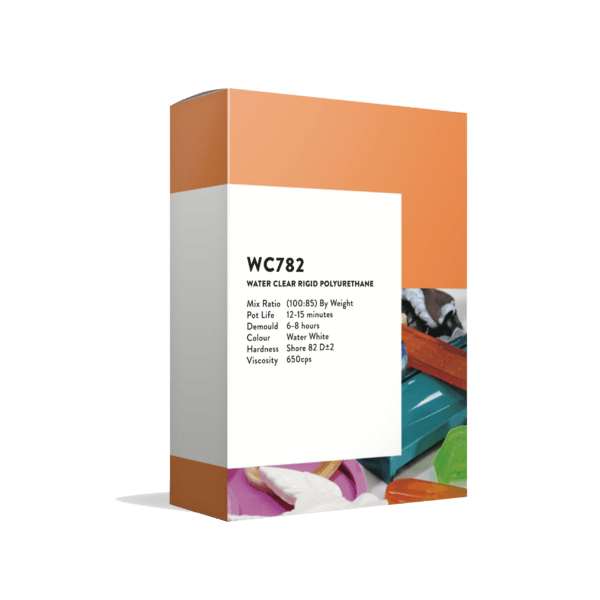

WC782 Water Clear Rigid Polyurethane

WC-782 A/B is an impact resistant, rigid, 82 Shore D material that is commonly used to make clear or tinted

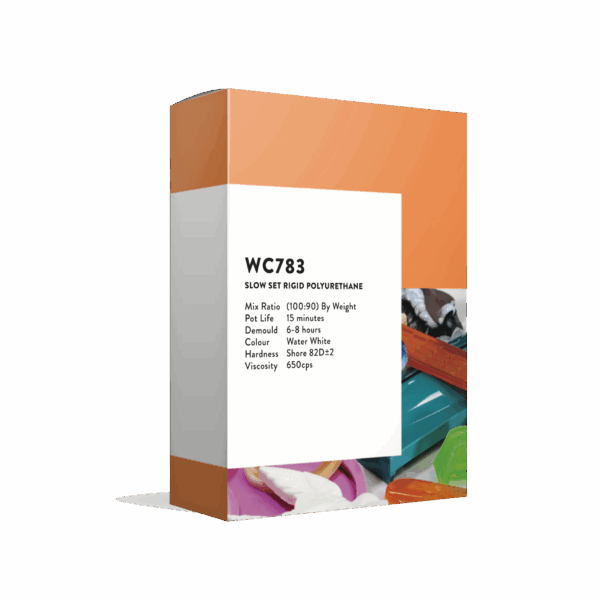

WC783 Water Clear Rigid Polyurethane

WC-783 A/B is an impact resistant, rigid, 82 Shore D material that is commonly used to make clear or tinted

WC784 Water Clear Rigid Polyurethane

WC-784 A/B is an impact resistant, rigid, 82 Shore D material that is commonly used to make clear or tinted

WC786 Water Clear Rigid Polyurethane

WC-786 A/B produces a high impact, rigid, 80 Shore D material that is commonly used to make clear or tinted

Poly Optic 1411 Clear Casting Resin

Poly-Optic® 1411 Clear Casting Resin is a two-part, liquid polyurethane resin that cures (RTV) to a water-clear, Shore D80 plastic.

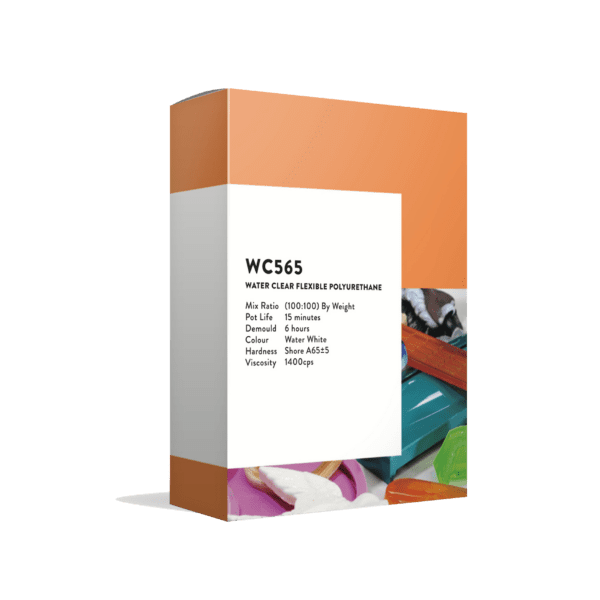

WC565 FLEXIBLE WATER CLEAR POLYURETHANE

WC-565 A/B is a two-part, water clear, colorless aliphatic based polyurethane elastomer. It is recommended for use whenever a flexible,

WC595 FLEXIBLE WATER CLEAR POLYURETHANE

WC-595 A/B is a two-part, clear, 90 Shore A polyurethane elastomer. It is recommended for use wherever a tough, flexible,

AF-7 Anti-Foaming Agent

AF-7 Anti-Foaming Agent has been developed as an extremely effective, air release agent for Water Clear polyurethane material systems. Its

Poly Purge Dry Air

Spray Poly Purge into open polyurethane Part A and B containers just before resealing to displace moist air and extend