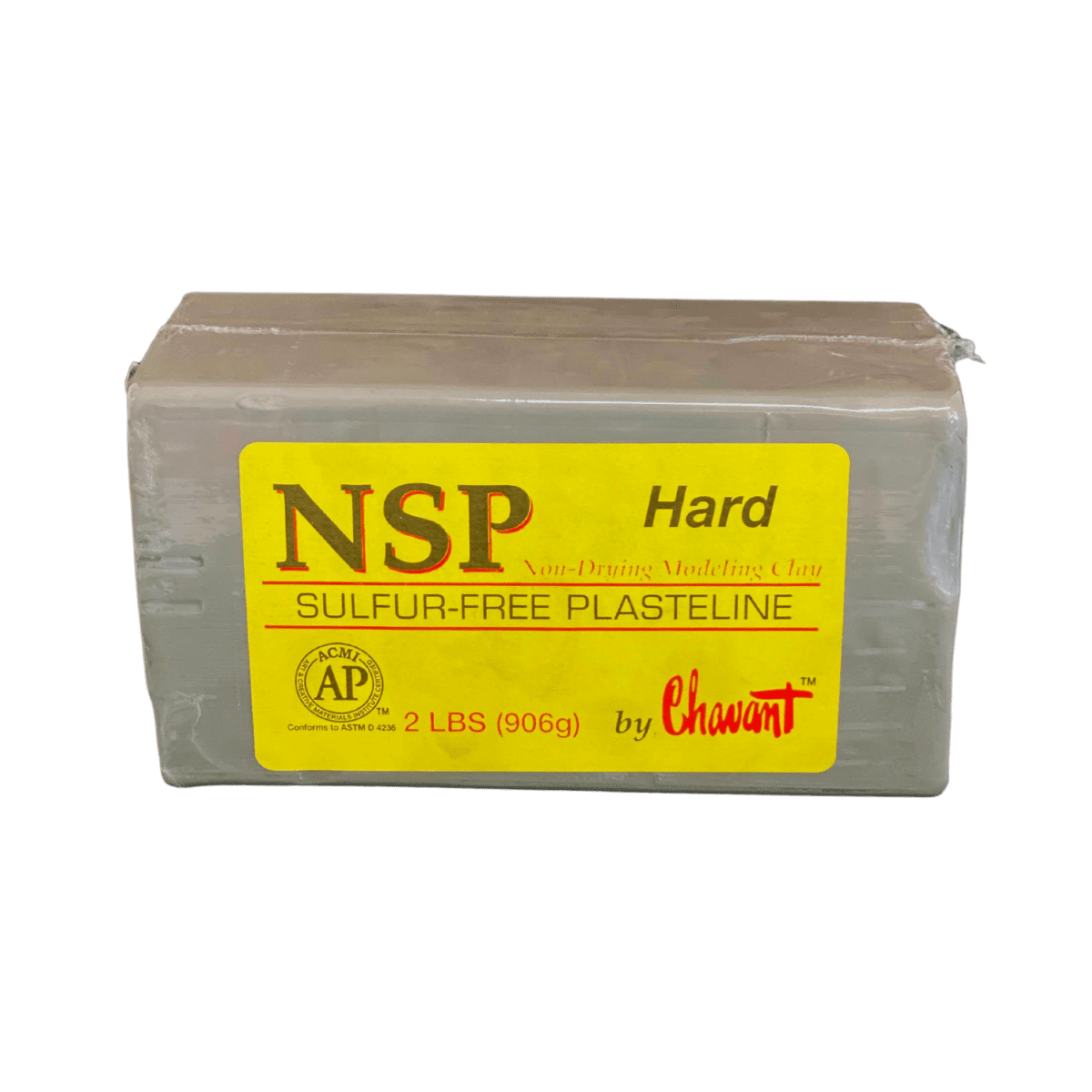

Chavant NSP clay is a globally well-accepted non sulfur modeling clay used by the Special Effects and Fine Arts industries. It holds exceptional surface details and is somewhat waxier and tougher than other Chavant products. NSP was introduced in 1993. The intention was to eliminate the sulfur filler in a professional grade sculpting clay, which often caused inhibition problems with various liquid rubber mold-making materials. As of September 2024, tests performed on recent batches of NSP in-house and by industry professionals, have resulted in mild inhibition against addition/platinum cure silicones. Please conduct a test first to ensure compatibility.

The NSP product line consists of clays that contain higher percentage of wax components making the clays somewhat “tougher”. Available in Medium or Hard, these clays have good adhesive qualities, flexibility and length. Because they are “tougher” NSP tends to accept cut detail lines very cleanly, with no ragged edges. The surface texture of NSP will be somewhat “grabby” when compared to sulfur-based clays.

NSP is commonly used by artists for the creation of sculpture and is often used to fill cracks in industrial patterns or to build dams when making splash molds. Product designers who freehand sculpt also use NSP. NSP is subject to surface oxidation. If the clay is in its original package, it will have a long shelf life, certainly months and probably years. If the clay is repeatedly heated and cooled, oxidation is accelerated. Sometimes this characteristic is beneficial in handling or mold making since the surface can become harder.

Unique Properties

NSP can actually be melted and poured as a casting, brushed or sprayed.

Physical Properties

Hard Density: 103 lbs./cu. ft. Specific Gravity: 1.65 g/cm

Softening Temperature

150°F / 66°C

Troweling Temperature

175°F / 79°C

Brushing Temperature

185°F / 85°C

Casting Temperature

205°F / 96°C

Hygiene

Wash hands with soap and water after use.

Handling Tips

NSP can be warmed to soften but as it softens it also becomes sticky. Using small amounts of water, citrus-based solvents, lighter fluid, latex paint removers, turpentine or mineral spirits as a lubricant on the surface of the clay will help to attain a smooth surface.