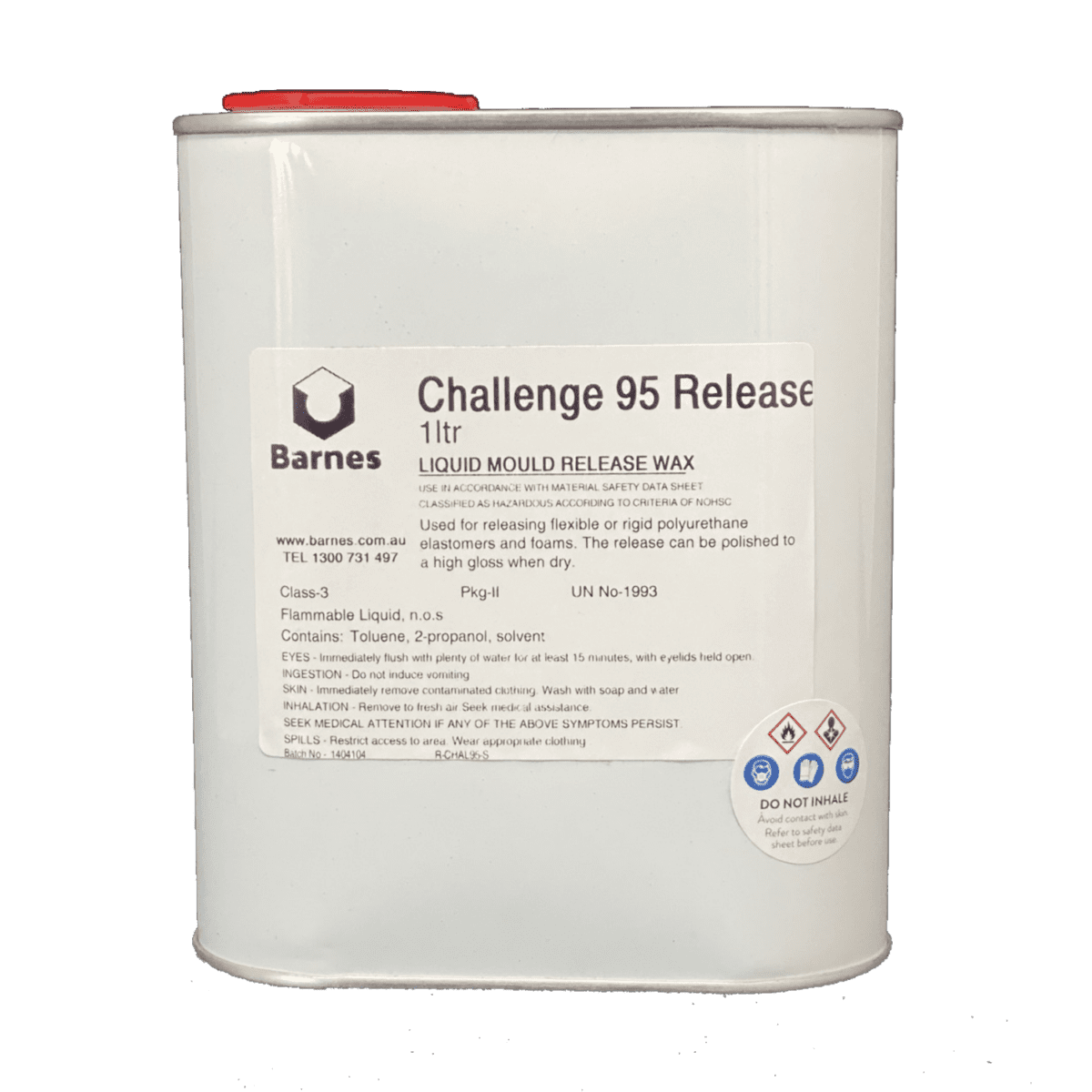

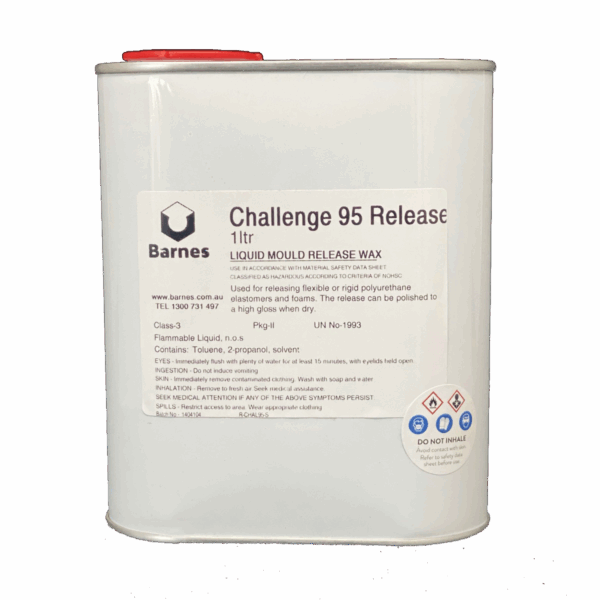

Challenge 95 is primarily a release for flexible and rigid polyurethane elastomers and foams. It can be used for other polyurethane systems as well, however, it is advisable to test prior to its use. Challenge 95 is a universal release for plaster, metal, urethane, and epoxy moulds. Challenge 95 dries at room temperature to create a uniform film. This release is a blend of synthetic and natural high temperature waxes dispersed in petroleum distillates.

Previous product

Back to products

Round Resin Art Board

$34.50 (inc. gst) $24.15 (inc. gst)

Next product

Stoner E236 Urethane Release

$51.75 (inc. gst)

Challenge 95 Release Agents

SKU: R-CHAL95-S

$97.75 (inc. gst)

SKU: R-CHAL95-S

Categories: Casting, Moulding, Release Agents, Release Agents

Related products

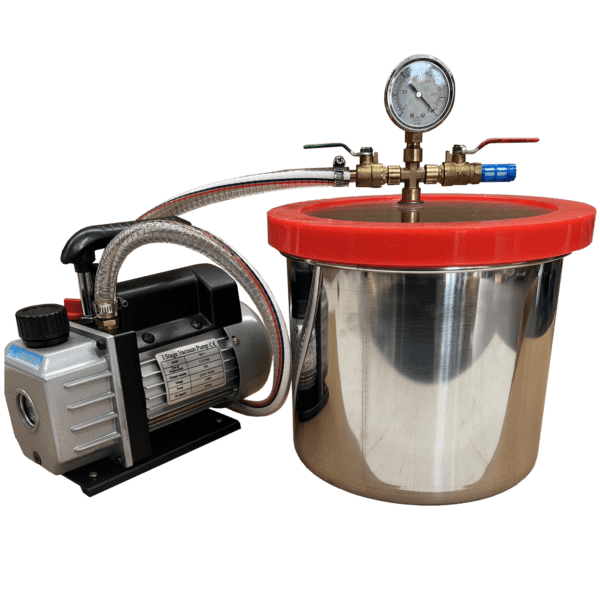

Barnes 6L Vacuum System

$632.50 (inc. gst)

This vacuum degassing unit is designed to remove air from resin and silicone systems prior to pouring. It is a

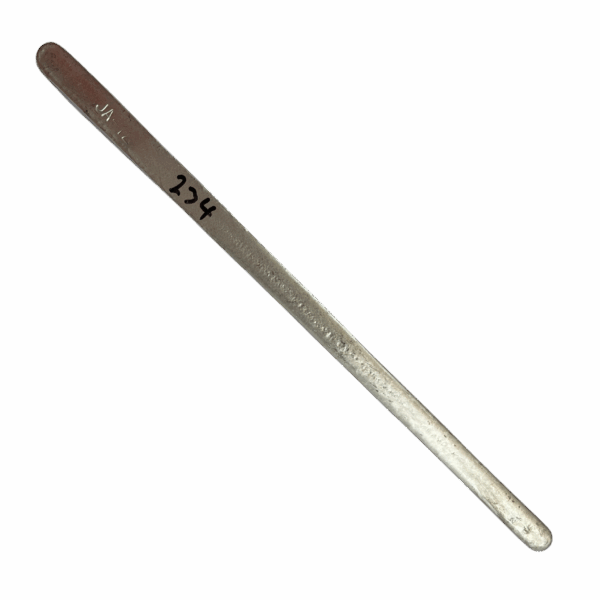

JA6 Alloy Stick

$230.00 (inc. gst)

*** Our website cannot supply custom weights, only per/kg – contact our Henderson store for a specific weight, as the average JA6 stick is between 220-310 grams***

Industrial Talc

From $18.40

Industrial Talc is a budget priced filler for reducing cost and exotherm in resins. Also used as a surface tension

Iron Powder

From $40.25

Iron powder fillers are more commonly used in resins for producing cold cast metal effects. Generally, higher amounts of metal

Chopped Strand Mat 600gm

$12.65 (inc. gst)

Our CSM 600gm is an emulsion chopped strand mat made of randomly distributed chopped E-glass strands held together by an

JA12 Alloy Stick

$212.75 (inc. gst)

*** Our website cannot supply custom weights, only per/kg – contact our Henderson store for a specific weight, as the average JA12 stick is between 210-280 grams***

Megapour Deep Cast Epoxy Resin

From $195.50

Megapour Epoxy Resin Deep Casting System is an epoxy resin system specifically designed for deep pouring and large castings. It

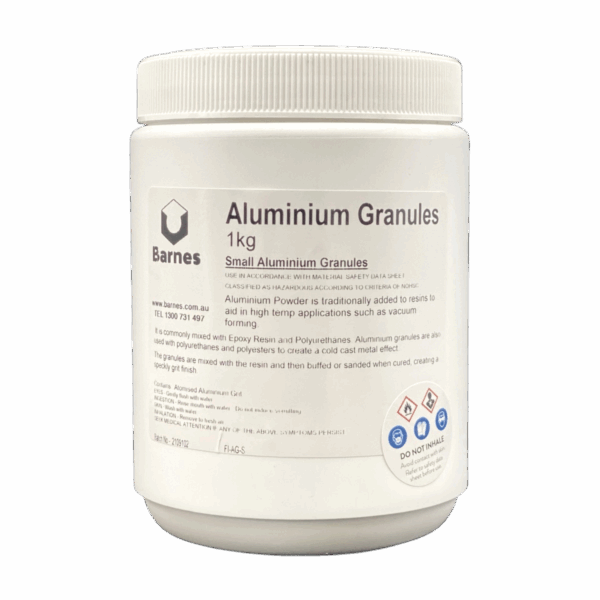

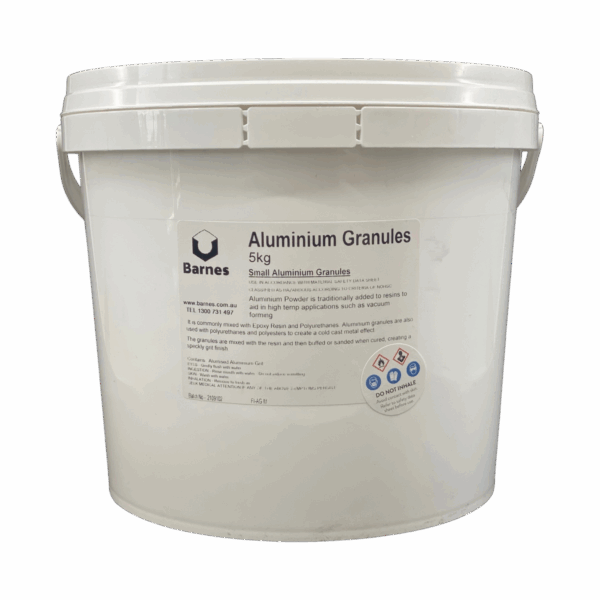

Aluminium Granules

From $57.50

Aluminium Granules are commonly used as a filler in resin moulds for vacuum forming and low pressure injection. Imparts high