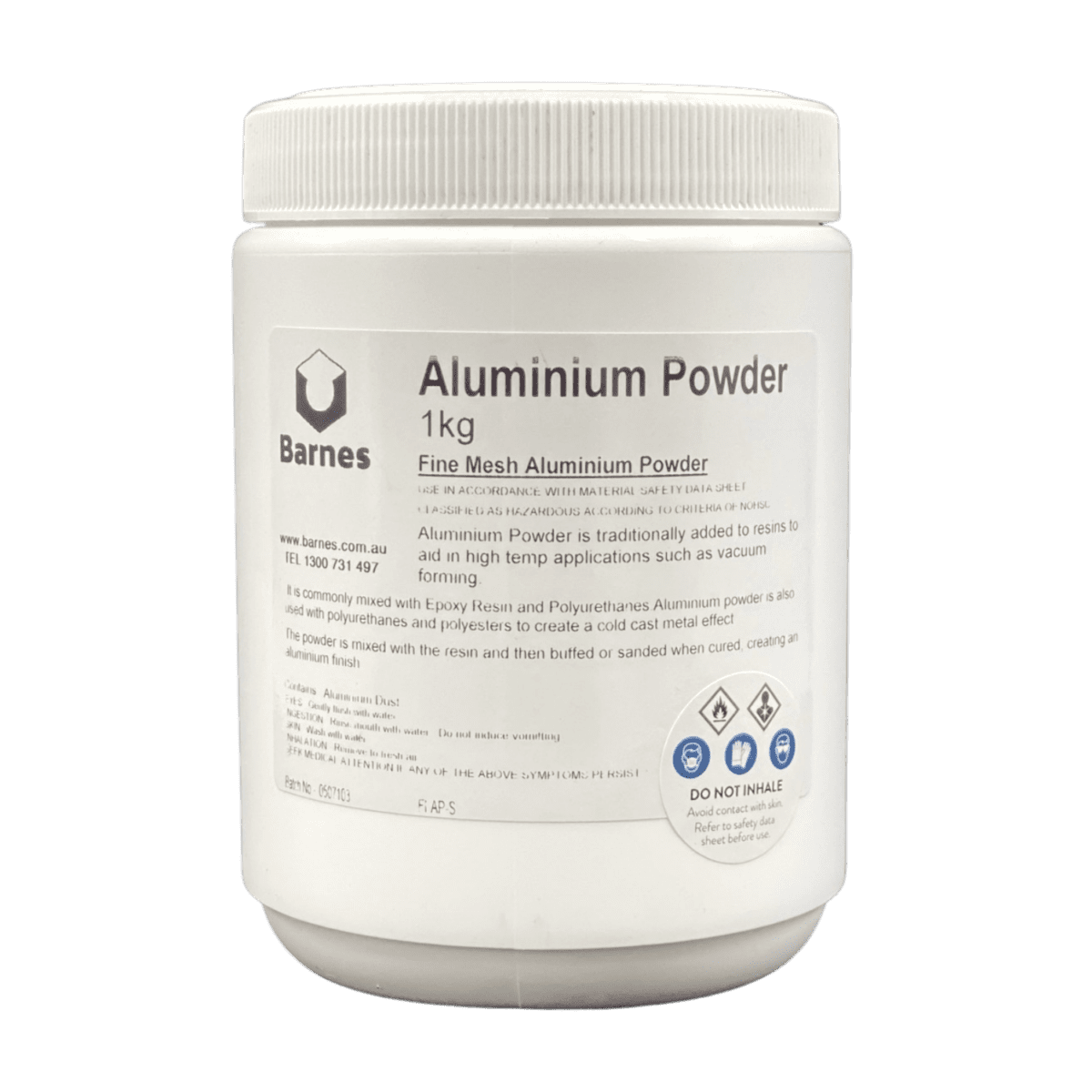

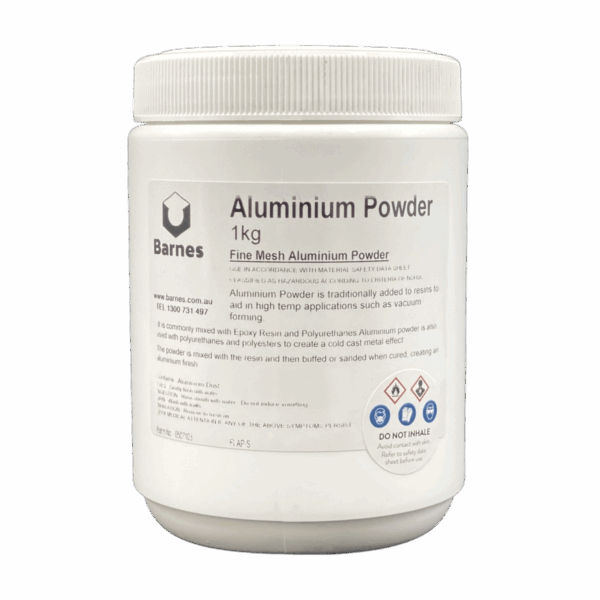

Aluminium Powder is traditionally added to resins to aid in high temp applications such as vacuum forming. It is commonly mixed with Epoxy Resin and Polyurethanes. Aluminium Powder is also used with resins to create a cold cast metal effect. The powder is mixed with the resin and then buffed or sanded once cured, creating an Aluminium finish. These powders give the ultimate metallic leafing finish in resin. Using only a smalll amount into your resin mix you can achieve the most amazing of metal looking finishes. This Aluminium Powder has an average particle size (D50) of 45 microns.

Previous product

Back to products

Surface Tissue

$7.48 (inc. gst)

Next product

Brass Powder

From $51.75

Aluminium Powder

SKU: FI-AP-T

$35.65 (inc. gst)

Related products

JA6 Alloy Stick

$230.00 (inc. gst)

*** Our website cannot supply custom weights, only per/kg – contact our Henderson store for a specific weight, as the average JA6 stick is between 220-310 grams***

Chopped Strand Mat 600gm

$12.65 (inc. gst)

Our CSM 600gm is an emulsion chopped strand mat made of randomly distributed chopped E-glass strands held together by an

Epoxyglass Clear Coating Epoxy Resin

From $92.00

EPOXYGLASS is a two part ultra clear epoxy coating resin used by professional artists and hobbyists Australia wide. EPOXYGLASS is

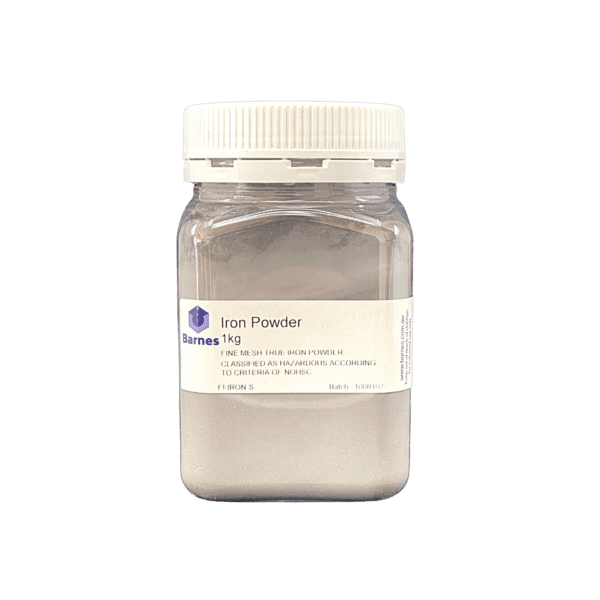

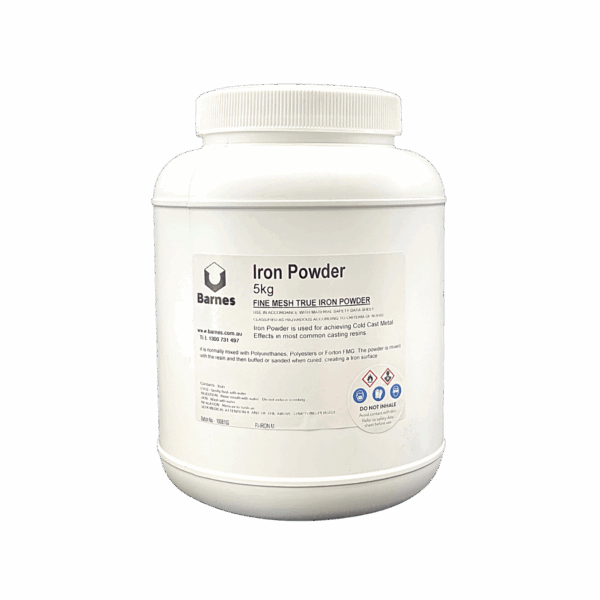

Iron Powder

From $40.25

Iron powder fillers are more commonly used in resins for producing cold cast metal effects. Generally, higher amounts of metal

Eye Dropper

$1.73 – $6.90 (inc. gst)

Eyedroppers are ideal for adding liquid pigments to resins, or for creating effects in resin art using Isoproyl Alcohol or

AntiCrak Fibre 13mm 500g

$40.25 (inc. gst)

The AntiCrak Fibre 13mm 500g is a premium Alkali-Resistant Fiber used for concrete crack control or gypsum casting. Low percentages

Langridge Dry Artist Pigment

From $27.60

Langridge Dry Artist Pigments offer gorgeous metallics, intense opaques and vibrant fluoros, that can be used to pigment our resin

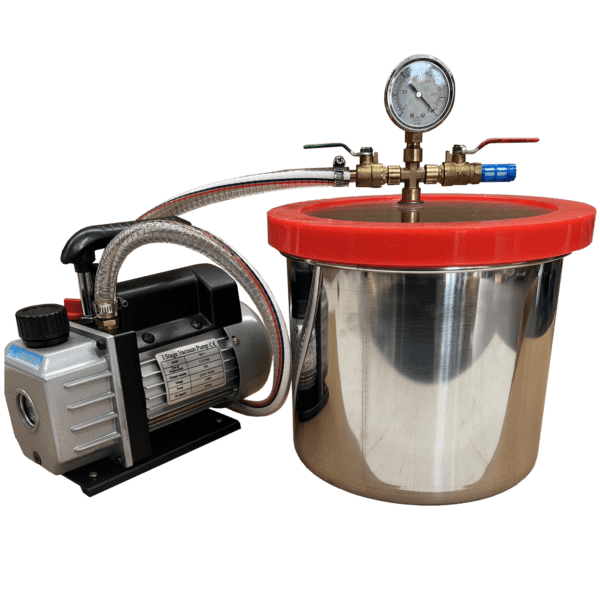

Barnes 6L Vacuum System

$632.50 (inc. gst)

This vacuum degassing unit is designed to remove air from resin and silicone systems prior to pouring. It is a